Dalam dunia togel Sydney, informasi mengenai live draw, hasil terbaru, dan data pengeluaran sangatlah penting bagi para pemain. Dengan adanya live draw sdy hari ini, para pecinta togel Sydney dapat langsung melihat hasil keluaran yang terbaru. Sdy pools merupakan tempat di mana hasil pengeluaran togel Sydney dipublikasikan, memberikan informasi yang akurat dan terpercaya kepada para penggemar togel sidney.

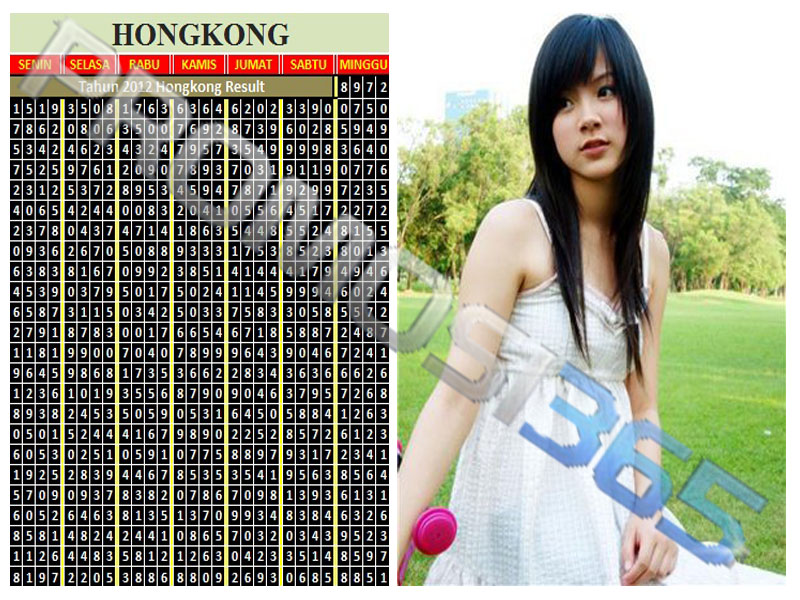

Togel Sydney telah menjadi permainan yang populer dan diminati oleh banyak orang. Dengan adanya togel sdy, para pemain memiliki kesempatan untuk memperoleh keberuntungan melalui prediksi angka-angka yang keluar. Data sdy yang dapat diakses memberikan kemudahan bagi para pemain untuk melihat statistik pengeluaran togel Sydney, sehingga mereka dapat membuat strategi permainan yang lebih baik. Selain itu, sydney pools merupakan tempat terpercaya untuk mengetahui hasil pengeluaran togel Sydney secara akurat dan tepat waktu.

Live Draw Togel Sydney

Di dunia perjudian online, live draw togel Sydney menjadi salah satu yang paling dinantikan oleh para pemain. Setiap hasil terbaru yang dikeluarkan menimbulkan antusiasme tinggi di kalangan penggemar togel Sydney. Dengan adanya live draw, pemain bisa menyaksikan secara langsung proses pengeluaran angka yang transparan dan fair. deposit 10 ribu

Togel Sydney pools menjadi tempat di mana para pemain dapat bermain dan bertaruh dengan harapan memperoleh keberuntungan. Data pengeluaran Sydney juga banyak dicari oleh pemain untuk menganalisis pola keluaran angka sebelumnya. Dengan informasi yang akurat, para pemain bisa mengambil keputusan yang lebih tepat dalam memasang taruhan.

Hari ini, live draw togel Sydney hari ini memiliki peranan penting dalam menentukan nasib para pemain. Dengan informasi hasil keluaran terbaru, pemain bisa segera mengetahui apakah angka yang dipasang telah keluar atau belum. Dengan demikian, live draw Sydney pools menjadi acara yang dinanti setiap harinya oleh para pecinta togel.

Hasil dan Data Terbaru

Dalam dunia togel Sydney, pemain selalu ingin tahu hasil dan data terbaru. Live draw SDY hari ini adalah momen yang paling dinanti-nantikan, di mana para pemain bisa melihat hasil undian secara langsung. Setiap keluaran SDY sangat penting bagi para pecinta togel Sydney.

Hasil dari pengeluaran SDY pools merupakan informasi yang sangat dicari oleh pemain. Dengan data SDY terbaru, para pemain dapat mengecek angka-angka yang keluar dan merencanakan strategi untuk taruhan selanjutnya. Tidak hanya itu, data pengeluaran SDY juga memberikan gambaran mengenai pola-pola angka yang sering muncul.

Togel Sydney menjadi topik pembicaraan yang hangat di kalangan pecinta togel. Dengan adanya live draw SDY, para pemain dapat merasakan sensasi dan ketegangan langsung saat angka-angka keluar. Semua informasi terbaru mengenai togel Sidney selalu dinantikan oleh para penggemar taruhan angka ini.

Togel Sidney Hari Ini

Untuk para pecinta togel Sidney, penting sekali untuk selalu update dengan data pengeluaran terbaru. Dengan mengetahui hasil live draw Sidney hari ini, Anda bisa merencanakan strategi permainan togel Anda dengan lebih baik.

Sydney pools menjadi sumber informasi utama bagi para pemain togel Sidney. Dari sana, Anda bisa melihat keluaran togel Sidney terkini dan memantau angka-angka yang keluar setiap harinya.

Jangan lewatkan kesempatan untuk memanfaatkan data Sidney terbaru agar dapat membuat prediksi yang lebih akurat dalam permainan togel Anda. Dengan mengikuti live draw Sidney hari ini, Anda bisa memaksimalkan peluang menang dalam togel Sidney.

Read More